Hose Diaphragm Piston - Delta Pompen B.V.

Main menu:

Brands

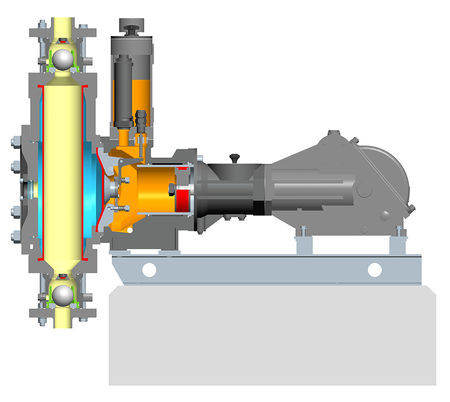

Feluwa Hose Diaphragm Piston

Pressure: up to 500 bar

Flow rates: up to 1,000 m³/h

Driving power: up to 5,000 kW

Process design

Each individual part that is theoretically subject to wear can be separately removed without prior dismantling of adjacent elements.

Modification of the traditional flat diaphragm into a hose-diaphragm

No settling in the clamping area.The diaphragms operate independently of each other and ensure operability as traditional diaphragm piston pump even in case of hose-diaphragm failure.

Each individual part that is theoretically subject to wear can be separately removed without prior dismantling of adjacent elements.

Modification of the traditional flat diaphragm into a hose-diaphragm

No settling in the clamping area.The diaphragms operate independently of each other and ensure operability as traditional diaphragm piston pump even in case of hose-diaphragm failure.

Even, linear flow path - No deviations. No settling.

Cassette design of delivery valves

Great variety of design options. Easy and fast removal by means of jack bolts. Linear flow path.

Great variety of design options. Easy and fast removal by means of jack bolts. Linear flow path.

Excess-pressure safety valve in the hydraulic fluid reservoir

Safety in case of blocked discharge pipe.

Safety in case of blocked discharge pipe.

Discharge pulsation dampeners (standard and hose-diaphragm designs) with in-built piston compressor

Minimum residual pulsation. High uniformity.

The hose-diaphragm, delivery valves as well as suction and discharge pulsation dampeners are in contact with the conveyed

fluid only. No settling in the clamping area of the flat diaphragm.

fluid only. No settling in the clamping area of the flat diaphragm.

Hermetically sealed. Double separation between wet end and hydraulic section.

Environmentally friendly. Leak-proof and quiet operation.

Tough design of pump heads - Numerous series to meet flow rates and pressure ranges.

Condition monitoring - Permanent condition monitoring of flat and hose-diaphragms as well as delivery valves.

The piston is working in oil. No sliding seals within the pump -

long intervals between maintenance. High reliability

long intervals between maintenance. High reliability